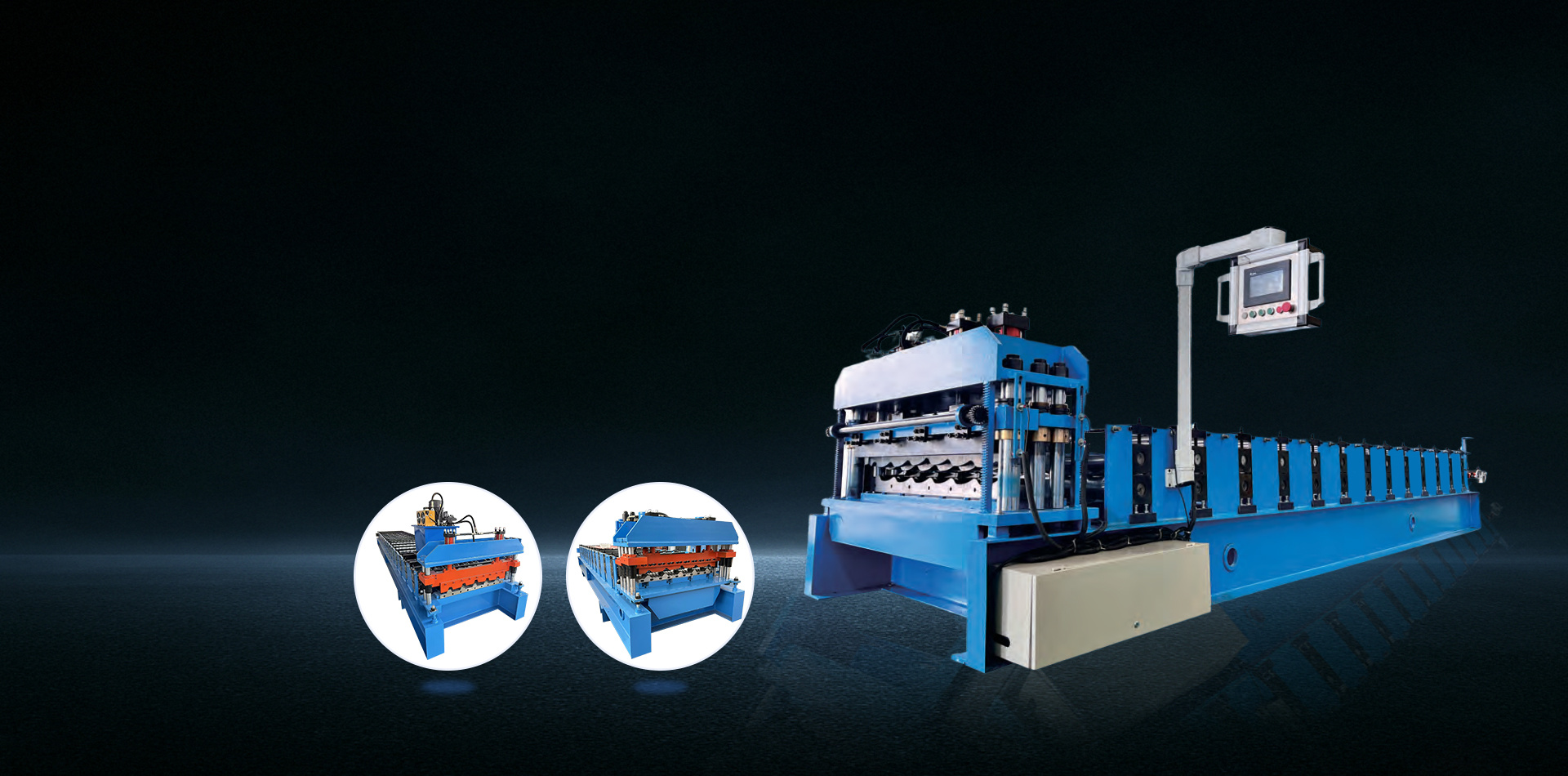

PRODUCTS

Providing customers with cost-effective

Full range of cold bending equipment

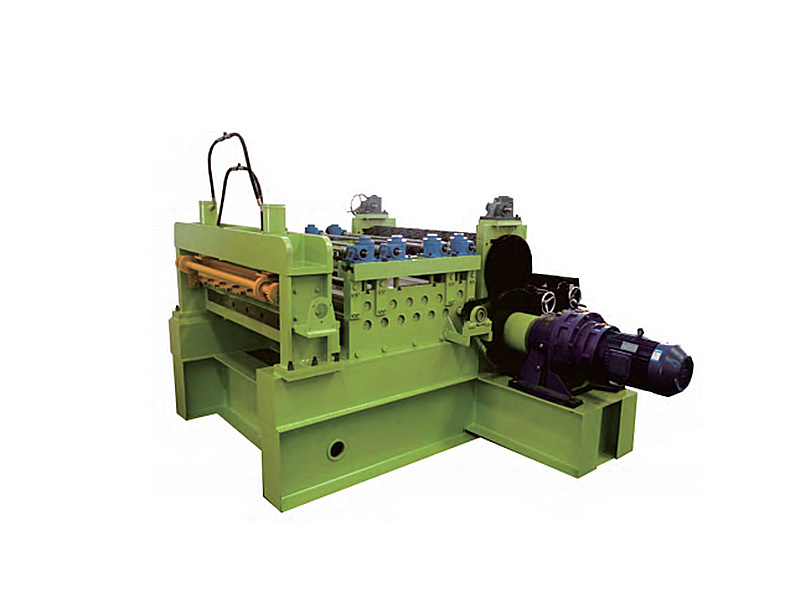

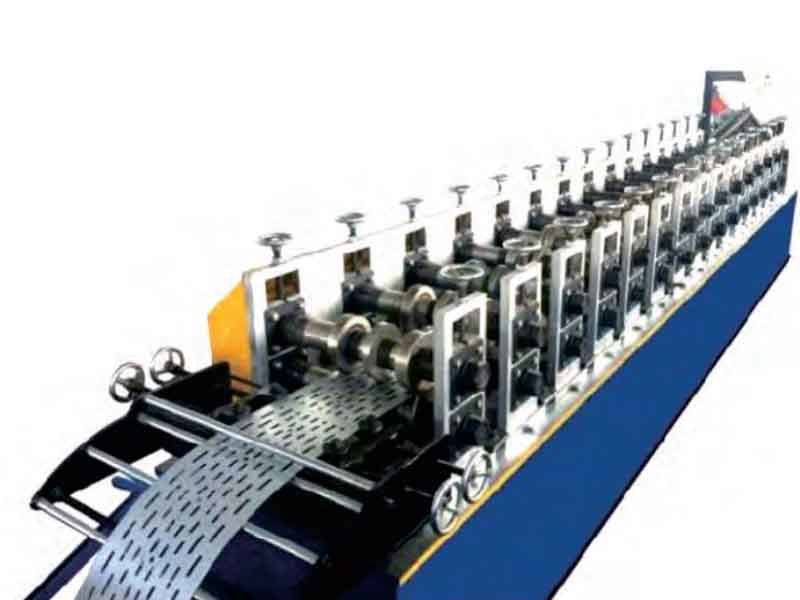

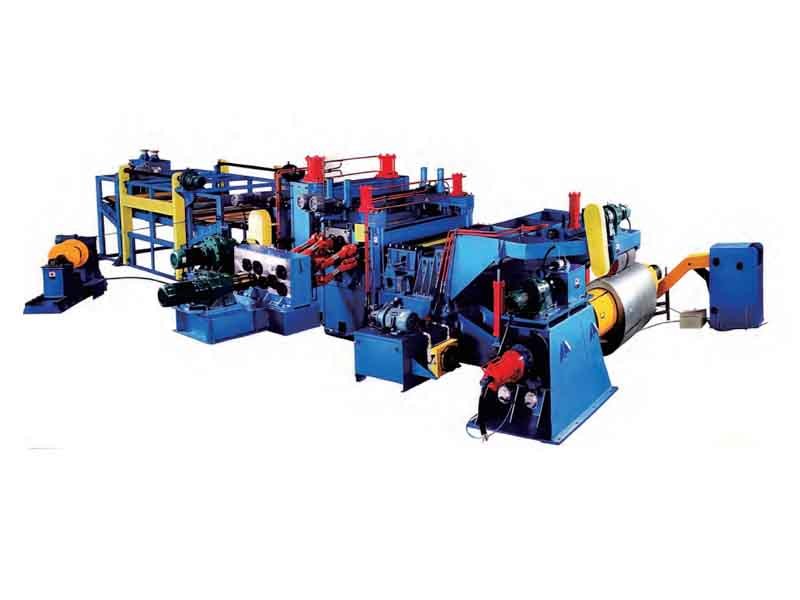

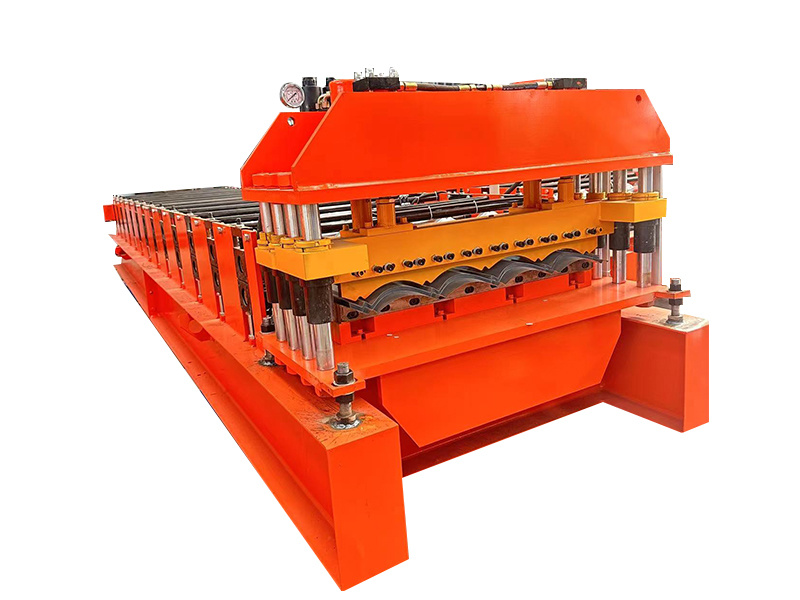

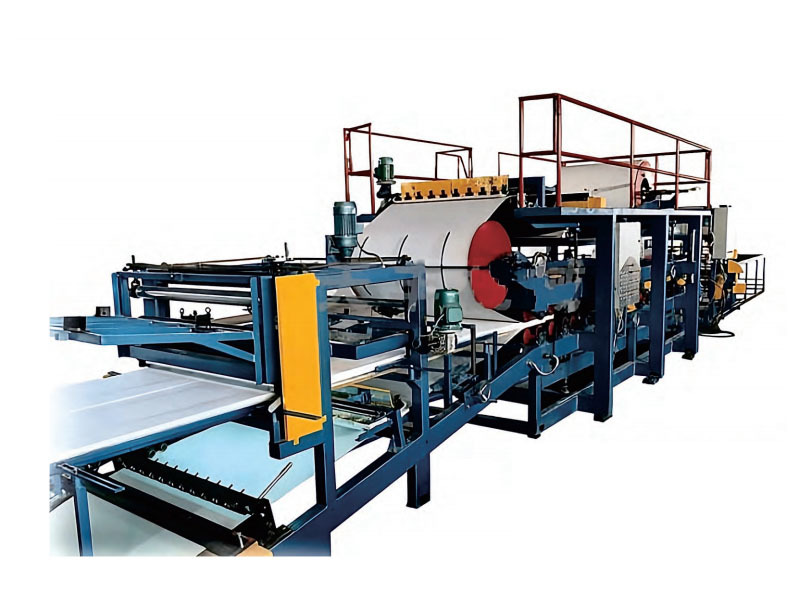

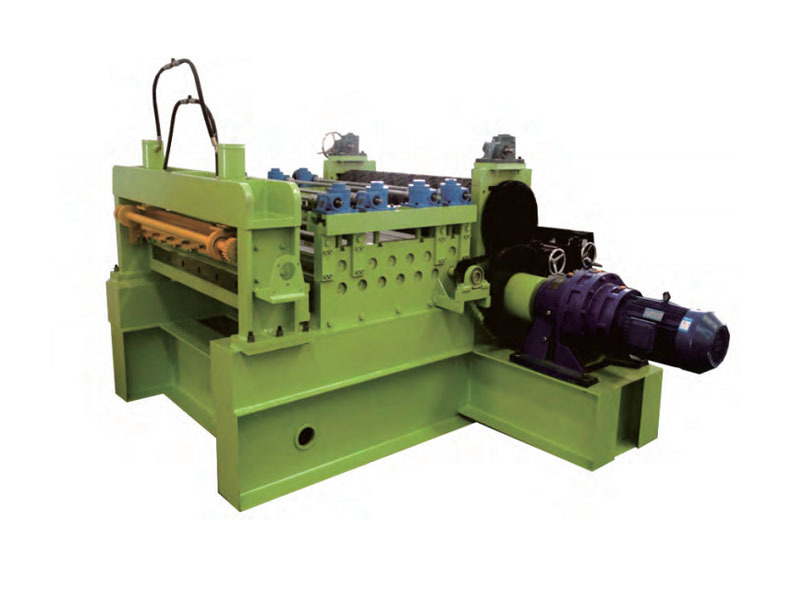

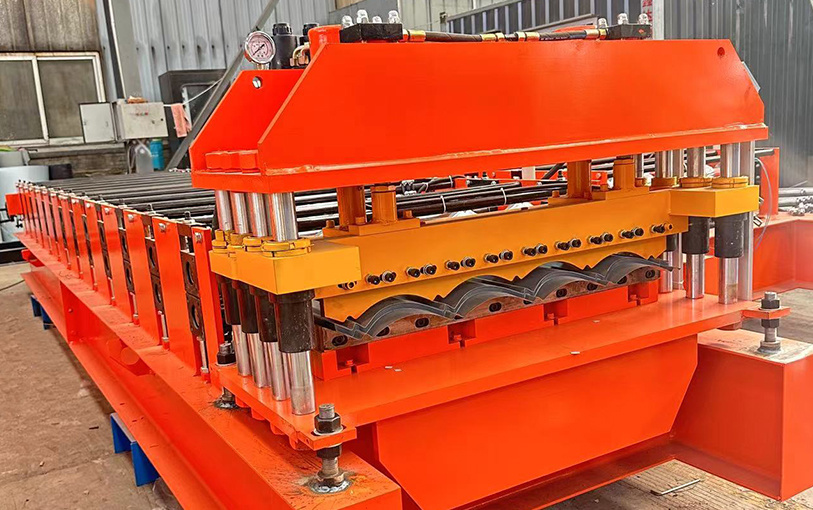

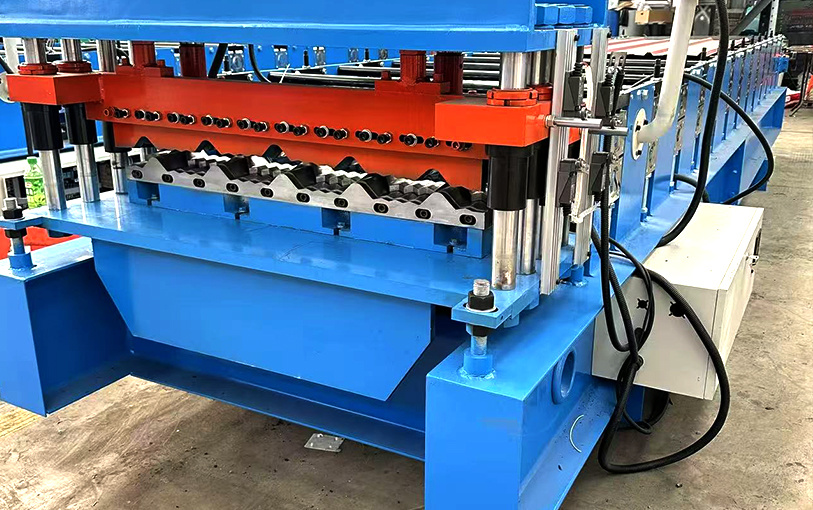

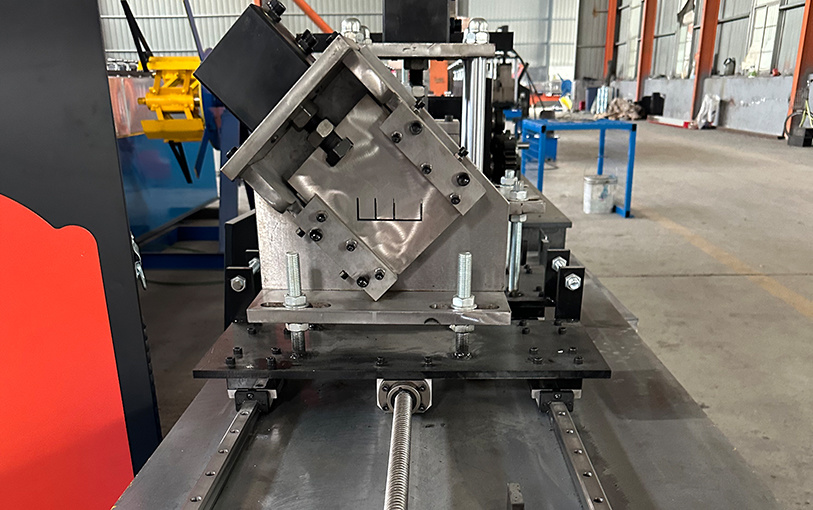

The company's main products include: single and double-layer color steel plate profiling equipment, glazed tile forming machines, C/Z type steel machines, keel machines, high-speed guardrail forming machines, roller shutter door forming machines, light steel villa forming machines, arch-shaped equipment, roll punching machines, shearing machines, bending machines, cable tray forming machines, and customized various special-shaped cold bending equipment.

RECOMMEND

Hot Product Recommendations

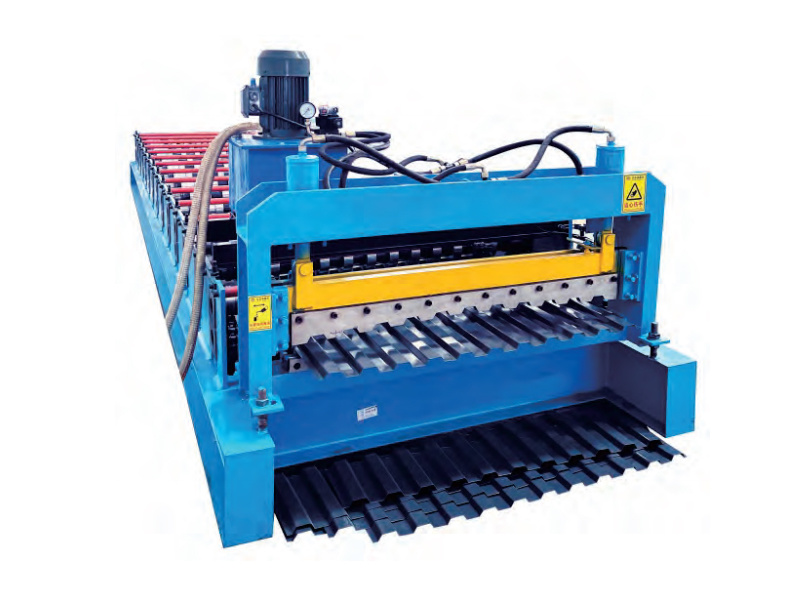

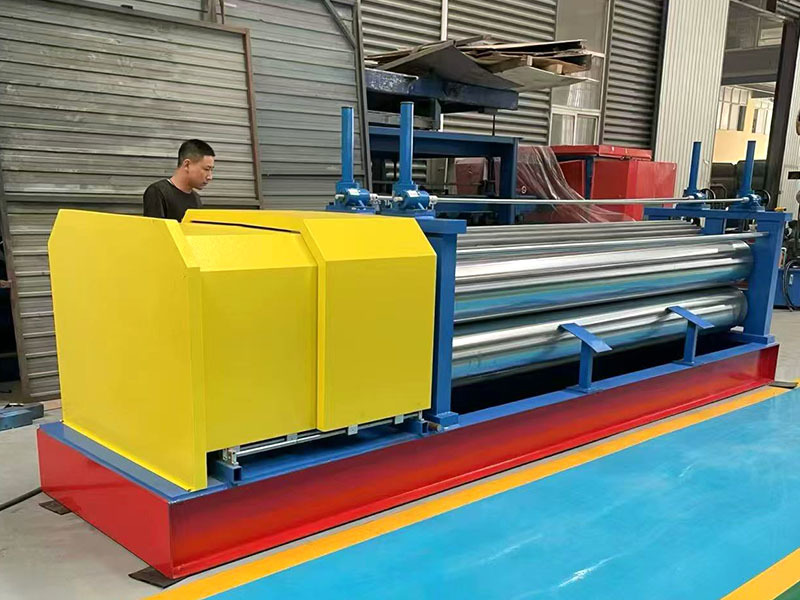

Insulation Composite Panel Production Line

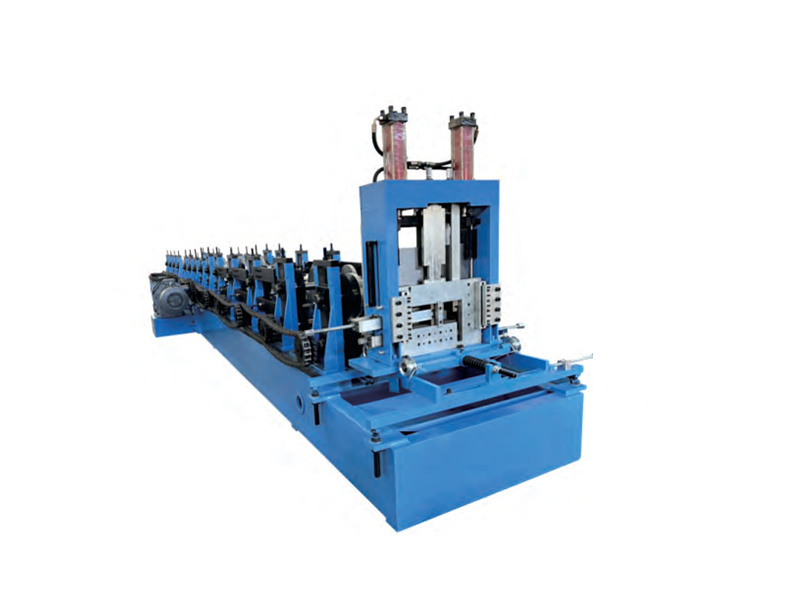

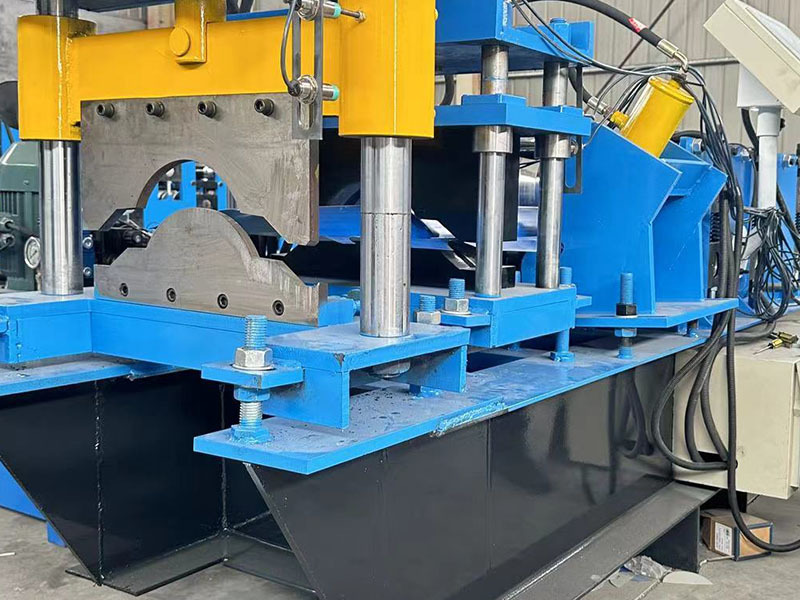

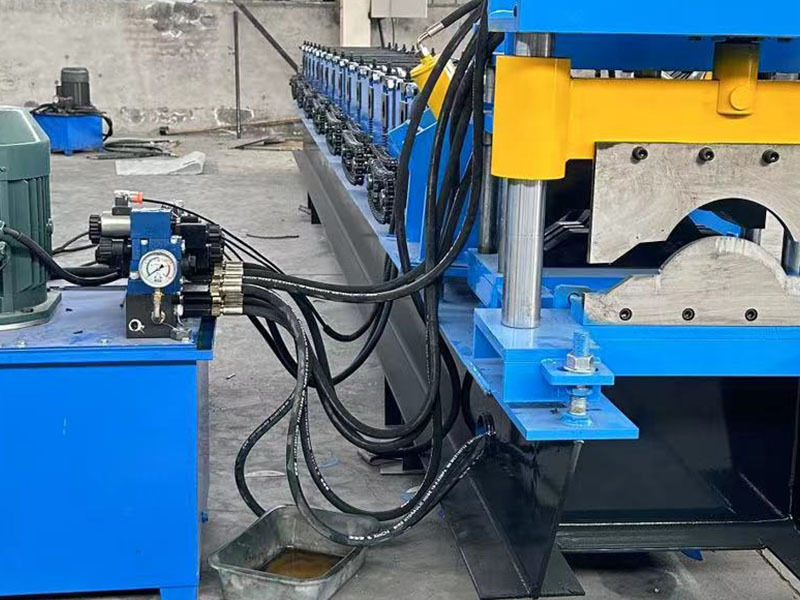

CZ Automatic Profile Steel Machine

ABOUT US

ZHANDA

A manufacturing enterprise mainly engaged in the design and manufacture of cold bending equipment

Founded in 2006, the company is a manufacturing enterprise focused on the design and production of cold bending equipment. The company covers an area of 15,000 square meters and has a complete design, production, and sales chain. The main products include: single and double-layer color steel plate profiling equipment, glazed tile forming machines, C/Z type steel machines, keel machines, high-speed guardrail forming machines, roller shutter door forming machines, light steel villa forming machines, arch-shaped equipment, roll punching machines, shearing machines, bending machines, cable tray forming machines, and customized various special-shaped cold bending equipment.

We firmly adhere to the development philosophy of quality as gold, perseverance, and integrity as the foundation, always uphold the enterprise spirit of pragmatism, innovation, and unity, steadily advancing towards the enterprise development goals, becoming a rising brilliant star in the industry.

The company's land area

Abundant inventory

Exported to foreign countries

CUSTOMIZED

One-stop solution for cold bending equipment products

We always put customers first and provide more service support. Whether it is product consultation, technical support, or after-sales service, we will wholeheartedly provide you with professional and timely assistance.

Better equipment, modern management.

Our professional R&D team and engineers create innovative solutions to meet the needs of our business partners.

We have many years of export experience, selling to more than 30 countries.

CUSTOMIZED PROCESS

Strict customization process to ensure quality and efficiency.

Sign Contract

Provide Custom Drawings

Merchant Quotation

Sign Contract

Processing and Production

Packaging and Delivery

Confirm Receipt

Successful Delivery

SOURCE FACTORY

Our Manufacturing Factory

The company is a modern machinery manufacturing enterprise integrating production, research and development, and sales, dedicated to providing customers with high-quality cold bending machine products and solutions.

Your One-Stop Solution!

Consult Customer Service Communicate Details

Confirm Plan Product Quotation

Product Sampling Confirm Sample

Order Payment Confirm Delivery Date

Mass Production On-Time Delivery

After-Sales Service After-Sales Evaluation

NEWS

BLOG